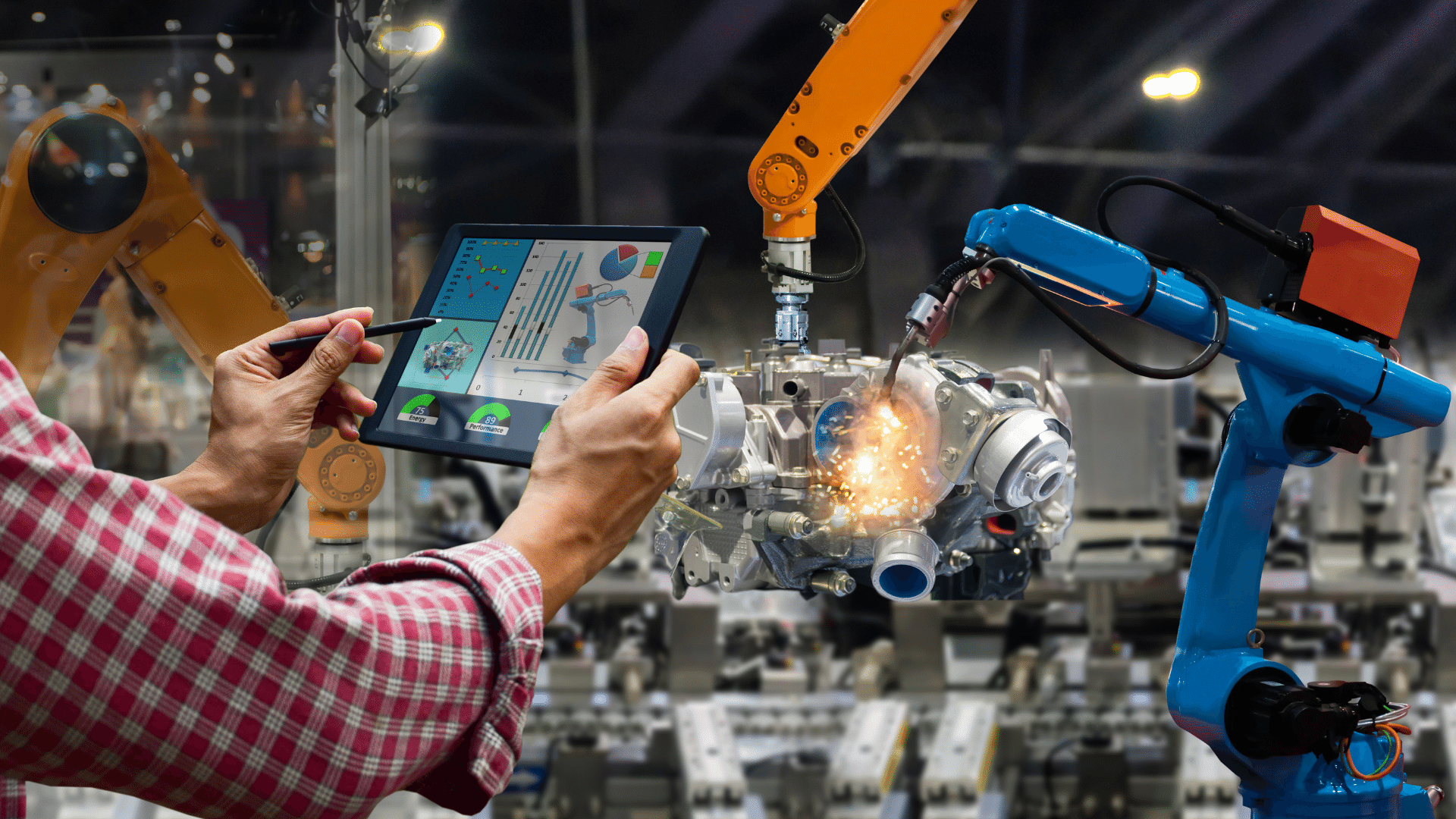

Industrial robotics is revolutionizing the manufacturing industry, with robots being used for various tasks such as assembly, welding, and material handling. To effectively work with industrial robots, professionals need to have hands-on experience and knowledge. In this blog, we will explore the role of hands-on training in industrial robotics and its benefits for professionals.

Hands-on training plays a crucial role in developing practical skills for working with industrial robots. Participants have the opportunity to interact directly with robots, learning how to program, operate, and troubleshoot them. This hands-on experience allows professionals to gain a deep understanding of the robot’s capabilities, limitations, and safety protocols. By working with robots in a controlled environment, professionals can build confidence in their abilities and become proficient in robot programming and operation.

One of the key benefits of hands-on training in industrial robotics is the ability to learn from real-world scenarios. Participants are exposed to common challenges and issues that arise when working with robots. Through hands-on exercises and simulations, professionals learn how to identify and resolve problems, optimizing robot performance and efficiency. This practical experience prepares professionals to handle complex situations in real manufacturing environments.

Hands-on training also promotes collaboration and teamwork skills in the field of industrial robotics. Participants often work in teams on robot programming projects or problem-solving exercises. This collaborative environment allows professionals to learn from each other, share knowledge, and develop effective communication skills. In the world of industrial robotics, where teamwork is often required for successful implementation, hands-on training prepares professionals for collaborative work environments.

Furthermore, hands-on training enables professionals to stay updated with the latest trends and advancements in industrial robotics. The field of robotics is constantly evolving, with new technologies and applications emerging regularly. Hands-on training ensures that professionals are equipped with the skills and knowledge to adapt to these changes. By working directly with robots and exploring new features and functionalities, professionals can stay ahead of the curve and remain competitive in the industry.

In conclusion, hands-on training is essential for professionals in the field of industrial robotics. It provides practical experience, fosters collaboration and teamwork skills, and keeps professionals updated with the latest advancements in the field. If you’re looking to enhance your career in industrial robotics, hands-on training is a valuable investment that will equip you with the necessary skills to excel in this rapidly growing industry.