The Benefits of Hands-On Training for Process Control Systems

Process control systems are critical components of industrial automation, used to monitor and control various processes in manufacturing plants. To operate these systems effectively, professionals need to have a thorough understanding of their functionality and operation. Hands-on training is an effective way to gain practical experience and knowledge in process control systems. In this blog, we will explore the benefits of hands-on training for process control systems.

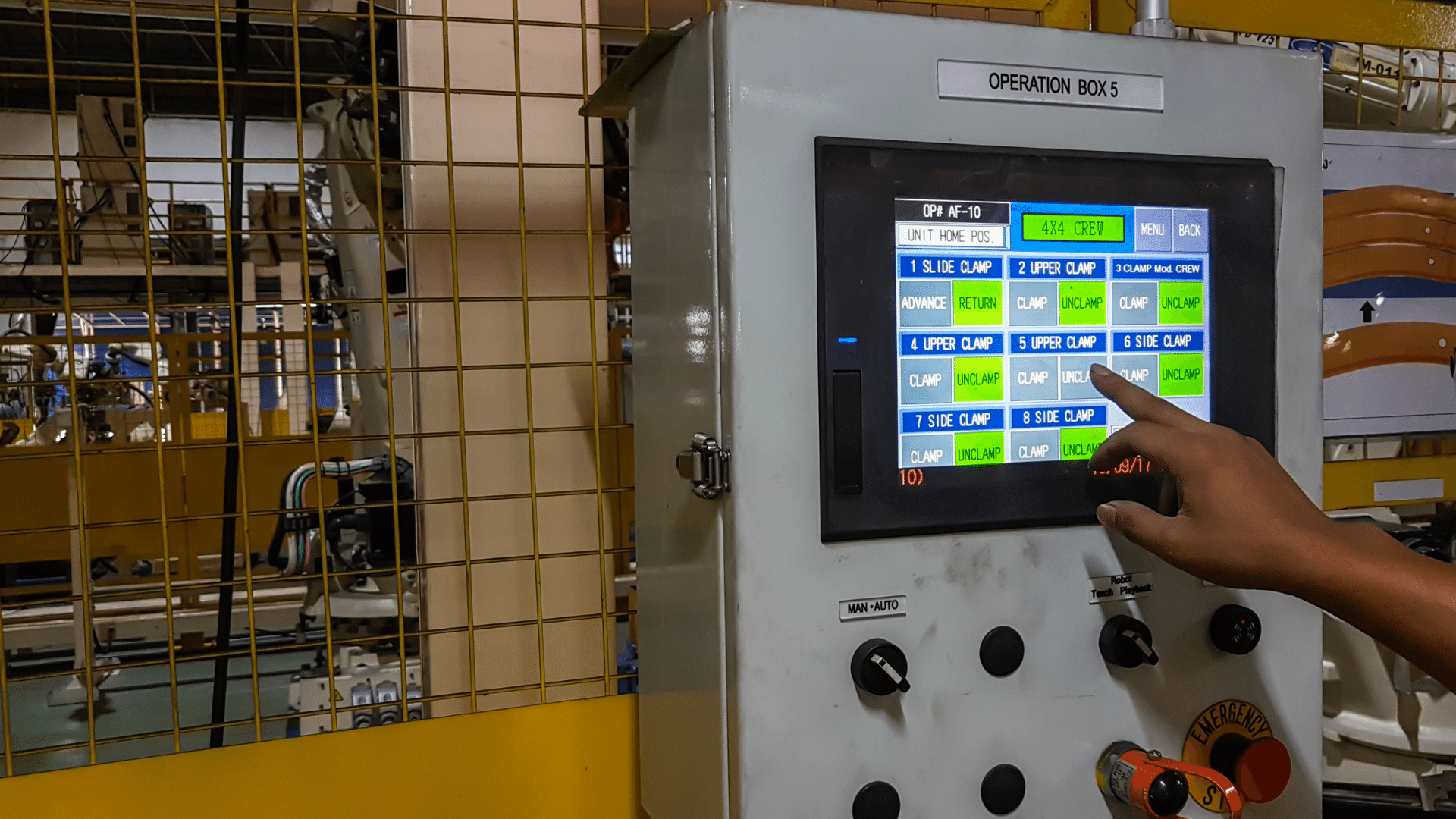

One of the key benefits of hands-on training for process control systems is the ability to gain practical experience with equipment and software. Participants can work directly with process control systems, learning how to configure, program, and troubleshoot them. This practical experience enables professionals to develop a deeper understanding of the system’s operation, leading to improved performance and efficiency in their work.

Hands-on training also promotes critical thinking and problem-solving skills. Participants are exposed to real-world scenarios and challenges, requiring them to analyze situations, identify issues, and apply logical solutions. This type of training cultivates a proactive mindset, allowing professionals to tackle problems efficiently and minimize downtime in industrial operations.

Furthermore, hands-on training enhances collaboration and teamwork skills. Participants often work in groups or pairs, simulating real industry scenarios where collaboration is essential for success. Through hands-on exercises and projects, professionals learn to communicate effectively, share knowledge, and work together towards common goals. These collaborative skills are invaluable in the process control industry, where teamwork is often required for large-scale projects.

Another benefit of hands-on training is the ability to adapt and learn new technologies quickly. The field of process control systems is constantly evolving, with new technologies and advancements emerging regularly. Hands-on training keeps professionals updated with the latest trends and equips them with the skills to adapt to new systems and software. This adaptability is crucial for staying competitive in the industry.

In conclusion, hands-on training is essential for professionals working with process control systems. It offers a dynamic learning experience that combines theoretical knowledge with practical application. Professionals who undergo hands-on training gain technical proficiency, critical thinking skills, collaboration abilities, and adaptability to new technologies. If you’re looking to enhance your career in process control systems, hands-on training is an investment worth considering.